Ceramics Additive Manufacturing Markets 2017-2028

$2,497.50 – $3,497.50

| Select User License | Single User License (one computer), Group User License (Up To Five Computers), Enterprise User License (Unlimited Computers Within Your Organization) |

|---|

Request Excerpt

Chapter One: The Continuously Evolving Role of Ceramic Materials in Additive Manufacturing

1.1 Key Indicators that the Ceramics AM Market is Growing

1.1.1 Large Industrial Groups Driving Innovation

1.1.2 Ceramics AM Expanding into Low-cost Accessibility

1.1.3 Cement Materials Extrusion Growing Larger

1.1.4 Enter Glass

1.1.5 Cross Segment Drivers

1.2 Overview of Ceramics AM Materials

1.3 Primary Ceramic 3D Printing Technologies

1.3.1 Stereolithography

1.3.2 Binder Jetting and CIM

1.3.3 Material Extrusion (MEAM)

1.4 Industrial Segments of Application for Technical Ceramics

1.4.1 Electronics and Optics

1.4.2 Aerospace and Defense

1.4.3 Automotive and Rail

1.4.4 Maritime and Energy

1.4.5 Biomedical and Dental

1.5 Industrial Segments of Application for Traditional Ceramics

1.5.1 Tooling, Foundry Cores and Molds

1.5.2 Art, Design and Consumer Products

1.6 Notable Trends in Major Adopting Industries for 3D-Printed Ceramics

1.6.1 Ceramics for Bioprinting Applications

1.7 Implementation Timeline

1.8 Summary of Ten-year Forecasts for 3D Printed Ceramics

1.8.1 Forecast of Ceramics AM Hardware Revenues by Segment

1.8.2 Forecast of ceramics AM hardware revenues by geographic locations

1.9 Methodology

1.10 Key Points from this Chapter

Chapter Two: Evolution of Ceramics Additive Manufacturing and Associated Markets

2.1 Stereolithography (Vat Photopolymerization) of Technical Ceramics

2.1.1 High-end Ceramics Stereolithography

2.1.2 Developments in Low Cost Ceramics Stereolithography

2.2 Ceramics Binder Jetting

2.2.1 Industrial Binder Jetting of Ceramics

2.2.2 Developments in Low-cost Ceramics Stereolithography

2.3 Pneumatic Extrusion Technologies for Ceramics

2.3.1 Industrial Extrusion of Traditional and Advanced Ceramics

2.3.2 Low-cost Ceramic Extrusion for Consumer Products

2.4 Current Status of Ceramics Selective Laser Sintering

2.5 Other AM Processes for Ceramics

2.5.1 NanoParticle Jetting

2.5.2 CIM-based Processes

2.6 Ten-year Forecasts of Ceramics 3D Printing Hardware

2.7 Key Points from this Chapter

Chapter Three: Ceramics Materials and Media Used in Different 3D Printing Technologies

3.1 Primary Ceramic Materials Used in AM

3.1.1 Zircon-based ceramics

3.1.2 Alumina-based Ceramics

3.1.3 Silicon-based Ceramics

3.1.4 Calcium-based Ceramics

3.1.5 Cement-based Materials

3.1.6 Clays

3.1.7 Glass

3.1.8 Ceramic Injection Molding (CIM) Materials

3.2 Slurry Ceramic Materials for Photopolymerization Processes

3.2.1 Zirconia in Photopolymerization Processes

3.2.2 Alumina in Photopolymerization Processes

3.2.3 Silica in Photopolymerization Processes

3.2.4 TCP and HA in Photopolymerization Processes

3.2.5 Ten-year Forecast of Ceramics Materials for Photopolymerization Processes

3.3 Powder Ceramic Materials for Binder Jetting Processes

3.3.1 Silica Sand

3.3.2 Zircon

3.3.3 Terracotta, Clay and Porcelain for Binder Jetting

3.3.4 Technical Ceramic Powders for Binder Jetting

3.3.5 Ten-year Forecast of Powder Ceramics Materials for Binder Jetting Processes

3.4 Paste Ceramic Materials for Material Extrusion Processes

3.4.1 Cements for Extrusion 3D Printing

3.4.2 Ceramic Materials for Microextrusion 3D Printing

3.4.3 Ten-year Forecast of Paste Ceramic Materials for Extrusion Processes

3.5 Ceramic Materials for Other AM Processes

3.6 Ten-year Forecast for Ceramics AM Materials

3.6.1 Total Materials Market Ten-year Forecast

3.6.2 Forecast of Ceramics AM Materials Revenues by Geographic Locations

3.7 Key Points from this Chapter

Chapter Four: Parts and Services

4.1 Ceramics AM Services

4.1.1 Specialized Technical Ceramics AM Services

4.1.2 Specialized Traditional Ceramics AM Services

4.1.3 Non-specialized AM Services

4.2 Ten-year Forecast of Ceramics AM Services

4.3 Ceramics AM End-users

4.4 Application Cases in Major Vertical Markets for Ceramics 3D Printing

4.4.1 3D Printing of High-performance Ceramic Parts for Aerospace, Automotive

4.4.2 Medical and Biomedical Applications

4.4.3 Dental applications

4.4.4 Jewelry and Luxury Goods

4.4.5 Electronics

4.4.6 Energy

4.5 Ten-year Forecast of Ceramics AM Parts Value

4.5.1 Forecast of Revenues and Unit Demand for Ceramics AM Applications

4.5.2 Forecast of ceramics AM applications revenues by geographic locations

4.6 Key Points from this Chapter

About SmarTech Publishing

About the Analyst

Acronyms and Abbreviations Used In this Report

List of Exhibits

Exhibit 1-1: Drivers for Adoption of Ceramics Additive Manufacturing

Exhibit 1-2: Ceramic Material Families Convergence

Exhibit 1-3: Map of the Leading Ceramics AM Technologies

Exhibit 1-4: Primary Ceramics Stereolithography Technologies and System OEM’s

Exhibit 1-5: Primary Ceramics Binder Jetting Technologies and System OEM’s

Exhibit 1-6: Primary Commercially Available Pneumatic Extrusion Technologies and System OEMs

Exhibit 1-7: Primary New Technologies for Ceramics AM and System OEM’s

Exhibit 1-8: Primary Potential Ceramic AM Applications and Expected Demand

Exhibit 1-9: Expected Timeline for Adoption of Ceramics AM Technologies in Final Parts Production

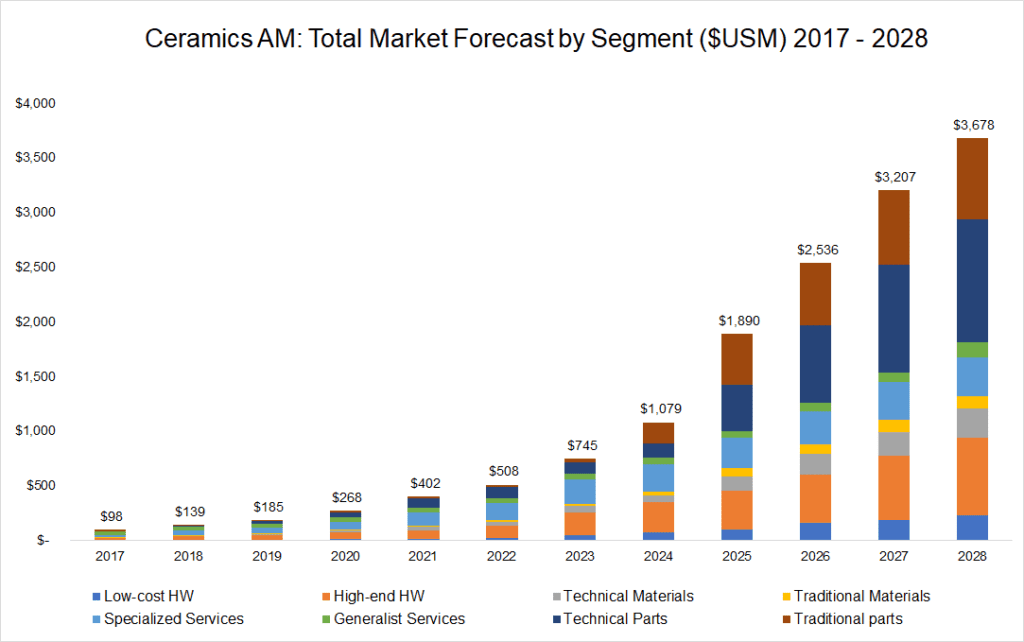

Exhibit 1-10: Overall market forecast for ceramics AM by segment

Exhibit 1-11: Segment CAGR for Ceramics AM

Exhibit 1-12:Ceramic AM Hardware Revenues by Geographic Location

Exhibit 2-1: High-end Stereolithography Systems and Sizes for Ceramics AM

Exhibit 2-2: Low-cost stereolithographic ceramic 3D printers

Exhibit 2-3: High-end binder jetting systems and sizes

Exhibit 2-4: Low-cost binder jetting systems and sizes

Exhibit 2-5: Industrial grade cement extrusion systems

Exhibit 2-6: Low-cost clay extrusion 3D printers and prices

Exhibit 2-7: Available material jetting systems for ceramics AM

Exhibit 2-8: How the Ceramics Injection Molding process works

Exhibit 2-9: Forecasted Average Price by Technology

Exhibit 2-10: Comparison between low-cost and high-end ceramics AM hardware revenues

Exhibit 2-11: Ceramics AM Hardware Unit Sales Growth Trend

Exhibit 2-12: Ceramics AM Hardware Revenues ($USM) Growth Trend

Exhibit 2-13: Ceramics AM Hardware Unit Sales

Exhibit 2-14: Ceramics AM Hardware Revenues

Exhibit 2-15: Ceramics AM Hardware Unit Sales by Technology

Exhibit 2-16: Ceramics AM Hardware Revenues by Technology

Exhibit 2-17: High-end ceramics AM hardware unit sales

Exhibit 2-18: High-end Ceramics AM Hardware Revenues

Exhibit 2-19: Low-cost Ceramics AM Hardware Unit Sales

Exhibit 2-20: Low-cost Ceramics AM Hardware Revenues

Exhibit 2-21: Forecast of ceramics AM hardware revenues by geographic locations

Exhibit 3-1: Graphic Map of Ceramics AM materials distribution by type, technology and quantities

Exhibit 3-2: Ceramic Materials for non-AM CIM Applications

Exhibit 3-3: Primary Commercially Available Ceramic Products for Photopolymerization Processes, Properties and Applications

Exhibit 3-4: Commercially Available Zirconia AM Materials for Photopolymerization

Exhibit 3-5: Commercially Available Alumina AM Materials for Photopolymerization Processes

Exhibit 3-6: Commercially Available Silicate Ceramics Material for Photopolymerization

Exhibit 3-7: Commercially Available Calcium Ceramics Material for Biomedical Applications

Exhibit 3-8: Demand of slurry ceramic materials for photopolymerization

Exhibit 3-9: Revenues from slurry materials used in photopolymerization

Exhibit 3-10: Commercially available ceramic products for powder-based processes, properties and applications

Exhibit 3-11: Demand of powder ceramic materials used in binder jetting

Exhibit 3-12: Revenues from ceramic materials used in binder jetting

Exhibit 3-13: Currently available materials for large format extrusion 3D printing

Exhibit 3-14: Commercially available materials for microextrusion 3D printing

Exhibit 3-15: Demand of paste ceramic materials for extrusion technologies

Exhibit 3-16: Sales of paste ceramic materials for extrusion technologies

Exhibit 3-17: Other Commercially Available Ceramic Materials for Additive Manufacturing

Exhibit 3-18: Forecast of total all materials sales in ceramics AM

Exhibit 3-19: Demand of ceramic materials for additive manufacturing by technology

Exhibit 3-20: Revenues from ceramic materials for additive manufacturing

Exhibit 3-21: A comparison between sales of technical versus traditional ceramic materials for additive manufacturing

Exhibit 3-22: Technical ceramic materials revenues by geographic location

Exhibit 3-23: Traditional ceramic materials revenues by geographic location

Exhibit 4-1: Go-to-market strategy for ceramics AM

Exhibit 4-2: Typical Process Workflow for AM of Technical Ceramic Parts

Exhibit 4-3: Total Ceramics AM Services Revenues

Exhibit 4-4: Specialized AM services vs. generalist AM services revenues for ceramic parts

Exhibit 4-5: Specialized AM services revenues from technical Vs traditional ceramics ($USM) 2017 – 2028

Exhibit 4-6: Generalist AM Services Revenues from technical Vs traditional ceramics ($USM) 2017 – 2028

Exhibit 4-7: Comparison Between Traditional and Technical Ceramics AM Forecast

Exhibit 4-8: Traditional ceramics AM parts value

Exhibit 4-9: Number of traditional ceramics AM parts produced

Exhibit 4-10: Technical ceramics AM parts value

Exhibit 4-11: Number of technical ceramics AM parts produced

Exhibit 4-12: Traditional Ceramics AM Parts Revenues by Location

Exhibit 4-13: Technical Ceramics AM Parts Revenues by Location

Contact Us for new report scheduled for Q2 2020

In this second report from SmarTech Publishing on ceramics additive manufacturing, readers will learn about the most up to date market data and analysis of market trends at the professional and industrial level. The report breaks down the ceramics 3D printing opportunity across numerous user industries as well as different AM technologies, materials and material supports, part types and geographical market regions.

The report analyzes pros, cons and generated revenues of the dominant AM technologies for processing ceramics, both technical (advanced) and traditional /(clay-like). These include material extrusion, photopolymerization and binder jetting 3D printing technologies. Currently available high-end industrial system data are complemented by a deep analysis of new and emerging technologies such as low-cost hardware systems and new jetting processes. All analyses are supported with hardware and material market shipments, sales, installations, and future forecasts through 2028 to provide a fully comprehensive insight into the future of ceramic 3D printing.

In 2018, the ceramics additive manufacturing market is focusing on AM part production, benefiting from the experience acquired by adopters and system OEM’s who are working with metal and polymer technologies. Ceramics AM, however, presents a distinct set of advantaged and challenges which are explored in detail in this report, along with the latest successful use cases. SmarTech Publishing believes that a proper understanding of the opportunity in ceramics 3D printing technology worldwide requires both a deep understanding of the individual nature of each print technology, but also an understanding of the interrelationship between these technologies and a specific family of ceramic materials, to fully understand how they can be integrated within current industrial manufacturing options.

Companies developing materials and providing ceramics additive manufacturing services or specific applications have come to understand that additive manufacturing’s extreme geometric capabilities are proving to ideal for production of complex ceramic parts in all major ceramic adoption segments. These include the aerospace, automotive, marine, energy, electronics, medical, dental and biomedical segments, which are already among the first adopters of AM technologies. In this report SmarTech will provide updated information on all major players and movers in the ceramic AM market, including Lithoz, 3D Ceram Sinto, Admatec, Prodways, Tethon 3D, 3D Systems, Kwambio, voxeljet, ExOne, HP, Johnson Matthey, Nanoe, XJet and several more.