By Scott Dunham

Vice President of Research, SmarTech Publishing

Recently, I’ve been talking to a lot of people in the 3D printing industry regarding competing polymer 3D printing processes and their future. During the research process for the latest SmarTech market research study, Additive Manufacturing with Polymers and Plastics 2018, I’ve had the pleasure of speaking with a range of leaders who are invested in moving the 3D printing industry forward –specifically towards a future in manufacturing, and specifically for printers that make things out of plastics and polymers.

One particular conversation was memorable because of how relevant it is to the industry today. An executive at a very respected polymer and plastics company compared the polymer printing industry, with its five widely established and utilized print processes all supported by various companies, to other technology development paths where a choice had to be made by the major supporting companies about which technology to support amongst several which would accomplish similar goals. In cases like the compact disc, or the VHS tape of the past several decades, those choices ultimately ended up determining an industry’s path.

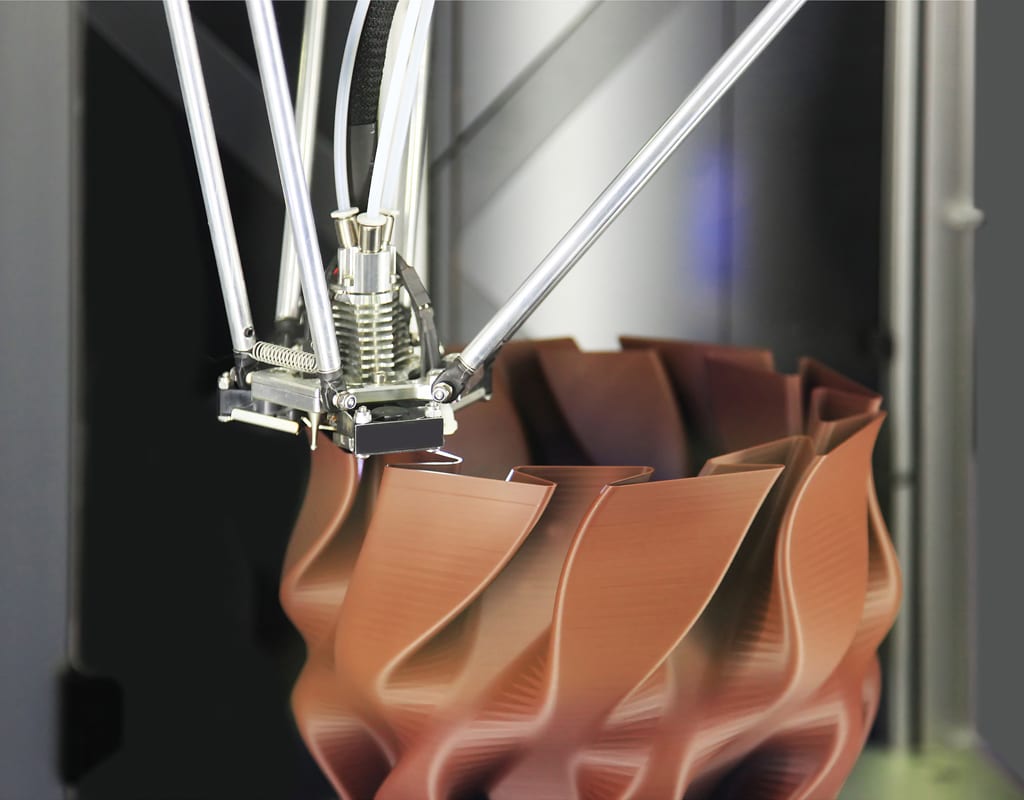

For polymer 3D printing, it’s fairly widely accepted that there are five available options to print a plastic part, and SmarTech defines these using the ASTM technology definition categories –material extrusion, powder bed fusion, vat photopolymerization, material jetting, and binder jetting. When we look to the future, which of the competing polymer 3D printing processes, if any, will remain in the future of plastic printing at a professional level? Perhaps the best way to analyze the question is to look at what is driving the interest in plastic printing today, and then look at how well each process serves this interest.

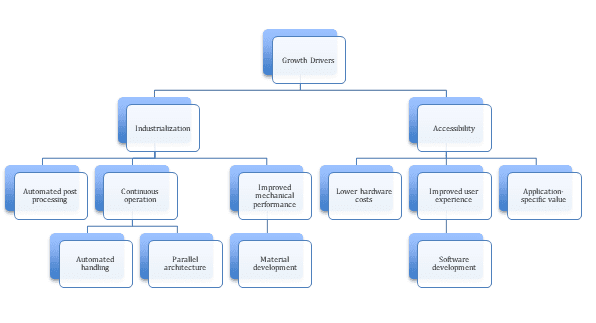

It should be undeniable, at this point, that the major interest area driving the market is in the use of printing to support manufacturing, and to ultimately engage in direct manufacturing of robust, end-use polymer and thermoplastic parts. Notice that this an interest area –quite different from the bulk of the activity which defines the plastic printing industry today, which is still prototyping. Prototyping will, by all accounts, continue to provide a level of industry baseline business for several years, but it is manufacturing support and direct manufacturing which will quickly become the growth engine of the market (just look at the growth in revenues from Materialise’s manufacturing segment compared to their prototyping segment over the last several quarters.)

Source: SmarTech Publishing

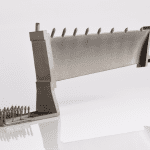

Polymer powder bed fusion, mostly characterized by selective laser sintering, is generally considered the most ‘industrial enabled’ plastic 3D printing process there is. This is because the technology can directly create the most all around mechanically robust parts while also being able to support volume production and scalability through efficient use of its building space in all dimensions, without the need to spend time designing support structures in parts. Though the technology is costly, limited in material choice today, and can waste material, there is no doubt that powder bed fusion is, on paper, is one of the most attractive choices for more industrially-oriented utilization. As a result, SmarTech’s latest published market forecasts in powder bed fusion predict this segment will generate the market’s largest share of hardware revenues within the next ten years.

However, don’t let that majority revenue share idea fool you –the actual estimate is that the majority share is only just over 30 percent by 2027, meaning that other print processes will control sizeable portions of the hardware spending over the next decade. Ignoring the industrial potential of print processes like vat photopolymerization and material extrusion, however, would be unwise given the technical developments which are ongoing in these areas.

The takeaway which was impressed upon me from this previously mentioned conversation was one which, ultimately many of us in the industry have arrived at independently. Unlike other tech of the past like the CD, with manufacturing technology, there isn’t a single concrete end goal to arrive at –one user may expect or desire a slightly different outcome from the next. And as a result of this, all of today’s plastic print technologies will continue to play an important role in polymer 3D printing over the long term (and likely even some which aren’t well established yet today).

Placing a bet on a single technology isn’t, of course, a bad idea in a market where there are multiple viable processes. Indeed, when looking at the hardware market for plastic printing today, a lot of the industry has been pushed forward by companies which have specialized in just one print solution. But from the perspective of supporting players, like those who will provide new material development, and ancillary technologies like material handling solutions and automated post processing systems, it’s better to be a position to support all these areas. This has been proven recently with both BASF and DSM –two leaders in 3D printing materials development –having restructured their additive businesses to create specific groups or product lines which focus on different print technologies.

Ultimately, there is industrialization potential across the board for polymer 3D printing, and capitalizing on this potential is the key to success in tomorrow’s industry. Each technology is developing its own unique approaches to creating more industrial appeal. As a current or potential future stakeholder in the industry, don’t overlook this point. Competing polymer 3D printing processes could be one of your biggest opportunities –or your biggest threat.