February 12, 2019

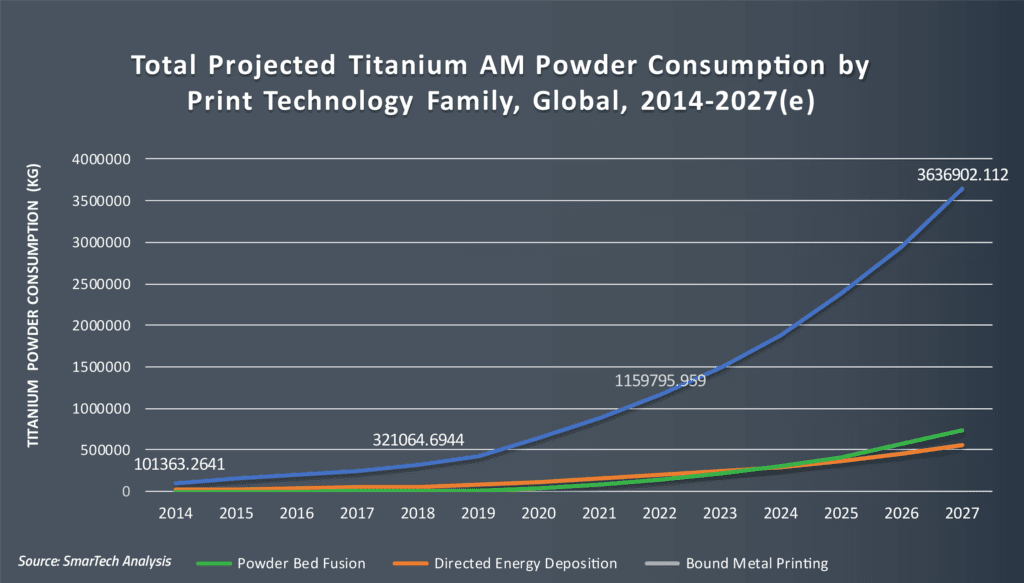

Crozet, Virginia: SmarTech, the leading provider of additive manufacturing market data and market analysis, has released a new titanium additive manufacturing forecast and market tracking database for titanium additive manufacturing (AM) opportunities which shows that shipments of titanium powders to AM users grew by 32 percent in 2018. SmarTech’s new data release also projects that 2019 will produce an additional 24% growth in titanium alloy revenues.

For more details on the report go to: https://additivemanufacturingresearch.com/reports/titanium-additive-manufacturing-2019-market-outlook-database/. A spreadsheet is available for persons interested in evaluating the report for purchase.

About the Report:

This two-part resource is the first of a new series of market intelligence offerings from SmarTech which provides stakeholders in titanium additive manufacturing an off-the-shelf resource for market metrics and forecasts specific to a high value segment of the industry. The analysis is both broad and deep, with tracked data covering material shipments and revenues by end user industry and geographic region, as well as by consuming print technology and other metrics. The data sets can easily be plugged into existing internal market intelligence resources or dissected to provide business intelligence across organizations. The accompanying report provides context for the data by analyzing the latest events and trends in the titanium powders AM market as they relate to various forecasted data.

From the Report:

- The titanium additive manufacturing forecast for 2019 continues to be tied to healthcare and aerospace activities, though an ever-increasing groundswell of interest and adoption of additive manufacturing in other industrial segments (including automotive, energy, consumer goods and heavy equipment) have helped keep plenty of attention on titanium even as other metals have made strides.

- To date, there have been two major drivers for adoption of additively manufactured titanium parts. These are in providing a solution for high strength to weight ratio components (which can have further weight optimization through generative designs enabled by additive processes), and in providing resilient biocompatible structures that can perform under the rigors of medical implant applications.

- On one hand, there is significantly broader appeal for use of additively manufactured titanium structures to serve lightweighting applications for structural parts in various systems compared to the scope of titanium’s use in healthcare applications. On the other hand, there seems to be great potential on the side of healthcare for major disruption utilizing additive manufacturing where an entire industry shifts to additive production, such as the area of orthopedic implants. This also provides an equally compelling argument for long term opportunities for titanium where such alloys are already very relevant and widely adopted using other means of production.