Charlottesville, Virginia: SmarTech Analysis, the leading provider of additive manufacturing market data and market analysis, has released a new market tracking and forecast database for steel additive manufacturing (AM) opportunities which highlights the rapid growth in steel AM powder shipments during 2018 of 48 percent –the greatest of any established metal in additive manufacturing. The new release is a two-part resource that provides users with tracking and forecast data for titanium powder shipments, revenues, pricing analysis, hardware opportunities, and more across the AM value chain. The database is accompanied by a report detailing current trends and factors affecting the titanium AM industry which influence the outlook in the data.

For more details on the report go to:

https://additivemanufacturingresearch.com/reports/additive-manufacturing-steels-2019/

About the Report:

This two-part resource is a continuation of a new series of market intelligence offerings from SmarTech Analysis which provides stakeholders in steel additive manufacturing an off-the-shelf resource for market metrics and forecasts specific to a rapidly growing segment of the industry. The analysis is both broad and deep, with tracked data covering material shipments and revenues by end user industry and geographic region, as well as by consuming print technology and other metrics. The package can easily be plugged into existing internal market intelligence resources or dissected to provide business intelligence across organizations. The accompanying short report provides context for the data by analyzing the latest events and trends in the steel AM market as they relate to various forecasted data.

From the Report:

• Steel is one of the only metals which is processed in every area of metal additive technology today, and is commonly introduced as a first material for new additive manufacturing platforms due to its widespread market appeal, non-reactive nature, widespread supply chain in powder form, low cost relative to other common AM materials, and more, making it of key strategic importance to the industry

• For the most part, the use of steel to directly produce additively manufactured end use parts is developing in areas which are outside of the primary historical markets for metal AM technology (which are medical and aerospace), which makes steels one of the keys to expansion of metal AM technology throughout the industrial world. Though there are plenty of opportunities today to utilize steel AM in both aerospace and medical contexts, steels are one of the fastest growing metal types in AM thanks to their use in supporting other industries which have an interest in additive manufacturing outside of these core areas

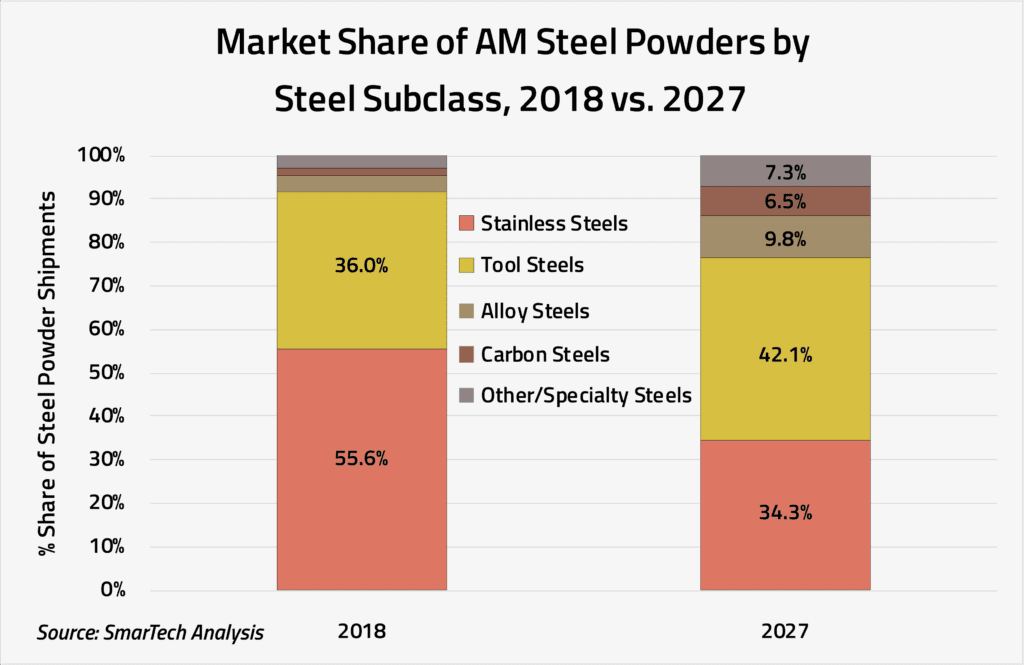

• Despite its popularity in additive applications, there are a very narrow group of steels which are commonly printed today relative to the vastness of steel opportunities which are currently utilized by traditional manufacturing processes across nearly every imaginable industry. It is estimated by SmarTech Analysis that there are only about ten primary steel alloys which are widely printed today, though certain private users are beginning to engage in material development for steels at a quicker rate which may have resulted in internal-only use of new steels for AM