Crozet, Virginia: SmarTech Analysis, the leading provider of industry analysis and market consulting services to the additive manufacturing industry, has released a new analysis model to address the opportunities associated with metal additive manufacturing production and applications. Using a new detailed analysis methodology comprising metal additive technology adoption metrics and dynamics already tracked by other SmarTech analysis services, this latest report provides critical insight into the industries and applications which are currently driving metal AM during its fledging years, and expectations for what business cases and areas of application will grow to the largest future opportunities.

Despite current challenges facing the metal additive market, SmarTech expects that metal AM will continue to gradually amass more and more production-oriented business cases, resulting in hundreds of billions of dollars in impact to the global manufacturing market over the next decade.

For more details on the report, go to: https://additivemanufacturingresearch.com/reports/metal-additive-manufactured-parts-produced/

About the Report:

SmarTech has provided a significant catalog of market opportunity research and analysis across metal additive manufacturing’s many adopting segments over the last seven years. These studies have been primarily focused on the primary elements of the market, especially the print technologies and resulting printing systems themselves, the materials utilized by these systems, related software, and the elements of operating such systems as a service to others exploring their use.

However, as metal additive technologies enter a more significant phase of production-oriented use where parts created are intended to enter service in marketable products or systems, a new opportunity analysis based on quantifying the production of parts by their intended use scenarios has become necessary in further assessing opportunities for growth and advancement.

Through its advanced market modeling techniques which have been adopted throughout the additive manufacturing industry to help inform and quantify market opportunities, SmarTech is now pleased to present a study and accompanying data set as a method of understanding metal additive manufacturing output, and its value to the various industries which metal AM users are active within. This research analysis is intended to help quantify the ways in which metal AM technologies are applied today and may be applied in the future, and the impact that these technologies will have on specific markets as time goes on.

The accompanying data set includes hundreds of data tables comprising an analysis of production activity and forecasts spanning metal AM technologies, regions, markets, and applications.

From the Report:

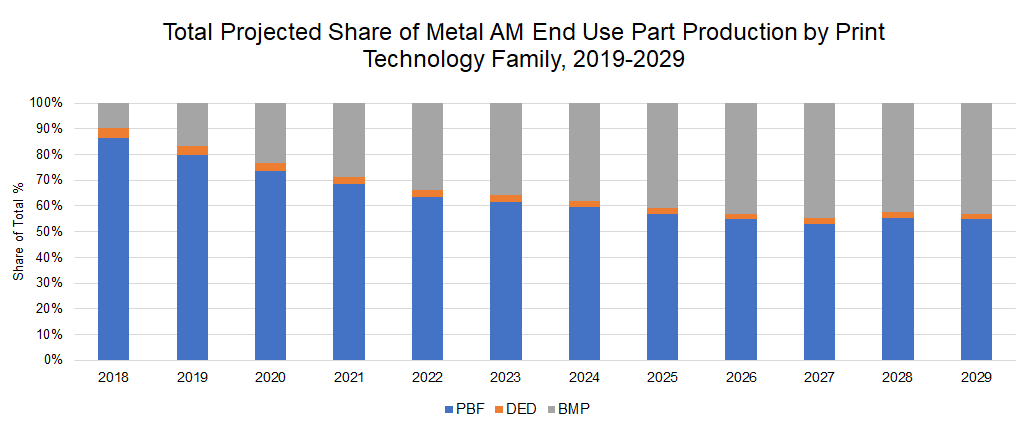

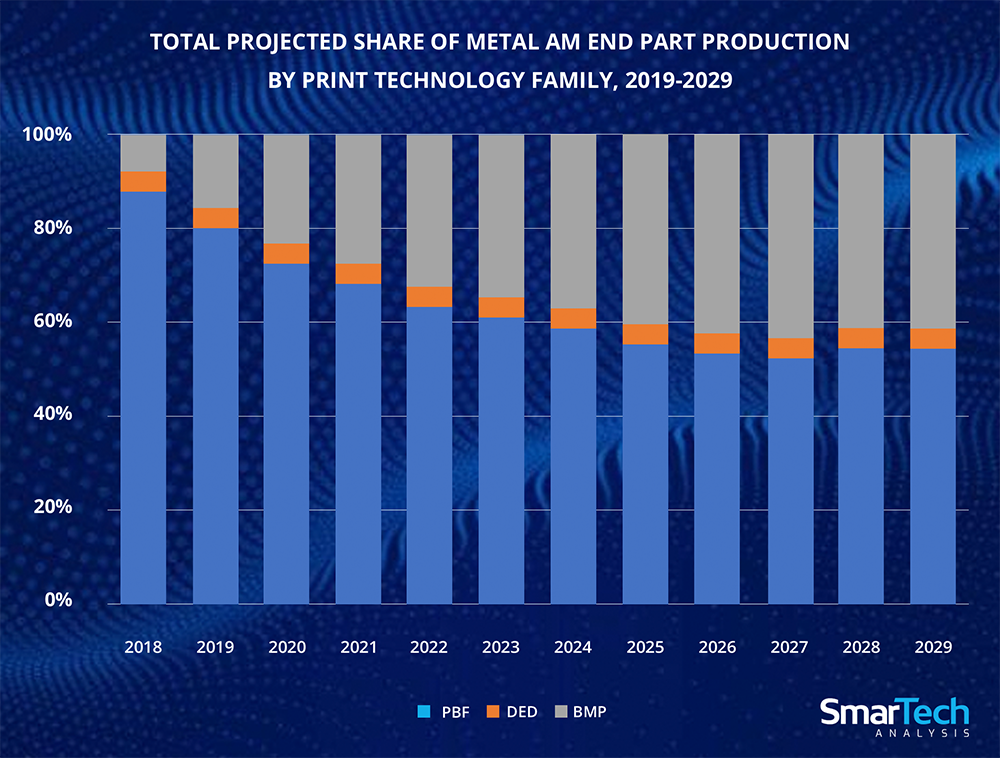

- Excluding metal AM in the dental applications, the rest of the metal AM industry is expected to shift from a prototyping-dominant technology to a production component dominant industry by the end of 2022. The burgeoning bound metal printing technology market will continue to drive notable growth in prototyping for metal components thanks to a lower cost structure and highly accessible systems, but ultimately production applications will account for 60 percent of market value from all produced components annually by the end of the forecast period.

- Several trends are expected to impact the production structure of metal additive technologies over the coming decade. Most significant are in designers consolidating assemblies into fewer parts which can only be produced by additive manufacturing. Also, efficiency and production-cost improvements of the individual technologies are slowly being realized through scalable deployments and efficient material handling and post processing. Across all technologies, markets, and applications, SmarTech anticipates that production costs associated with use of metal AM will fall 40 percent on average per-part by the end of the forecast period, despite part consolidation and performance trends.