Crozet, VA: Industry analyst firm SmarTech Analysis has just issued a new report addressing the management considerations for adoption of compact industrial metal 3D printing into end user and machine shops. The report is the next in a series of Manager’s Guides from SmarTech that focuses on the issues and perspectives for both potential and actual end users of additive manufacturing. The report, “Manager’s Guide to Compact Industrial Metal 3D Printers” is intended to help facilitate end users and machines shops with bringing this technology in-house.

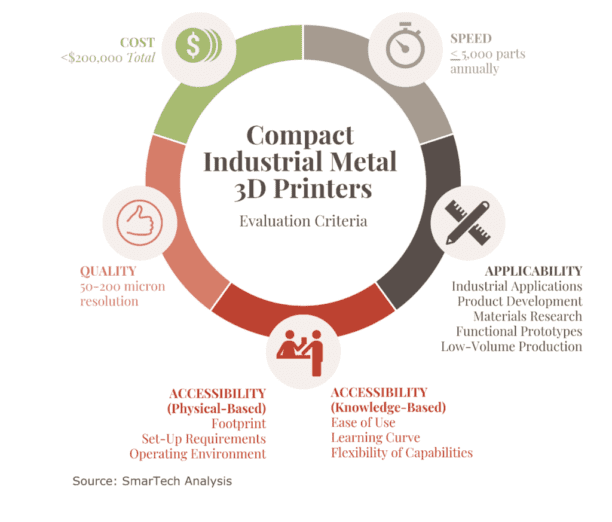

According to SmarTech, the ‘real’ metal desktop printers can be better described as “Compact Industrial Metal” 3D printers. These printers offer a more accessible price-point, shorter learning curve, and compact footprint, while still offering industrial-level quality. This class of metal printers addresses a significant hole in the marketplace and creates a lower-level entry point for new industrial users of metal 3D printing technology. Recognizing that Machine Shops are one of the most prolific emerging customers in this segment, SmarTech Analysis has utilized their research to create this new Manager’s Guide.

Details about the report are available at: https://www.smartechanalysis.com/reports/managers-guide-to-compact-industrial-metal-3d-printers/ including a description, TOC, and sample excerpt.

About the report:

This SmarTech Analysis report outlines the definition and applications of Compact Industrial Metal 3D printers. It includes a critical comparison of CNC machining vs. CIM 3D printers, a detailed review of notable Compact Industrial Metal (CIM) 3D printers and technologies, and a discussion on cost of ownership. This Manager’s Guide was developed to provide the necessary information to facilitate Machine Shops with bringing this technology in-house. The companies discussed include Markforged, Desktop Metal, Xact Metal, and Coherent, among others.

From the report:

When looking closer at Compact Industrial metal printers, the growth of metal AM as a whole will be aided directly and indirectly by the introduction and refinement of this growing class of metal 3D printers. Not only does the introduction of these new technologies give accessibility to a new group of customers, but they will greatly aid the education and further development of 3D printing as a manufacturing tool across industries and applications. These Compact Industrial metal printing solutions give accessibility to an entirely new segment of the market. With a total system cost of less than $200,000, and minimal set-up requirements, industrial customers now have an increasing number of options to aid in their exploration of metal additive manufacturing.

The most recognizable technologies in this market are the material extrusion technologies, specifically by Desktop Metal and Markforged, which are poised to grow dramatically. By borrowing heavily from materials science established within metal injection molding (MIM), bound metal deposition techniques are experiencing a much higher adoption rate than earlier AM technologies. It is within this subsegment that we are currently seeing a lot of growth for the Compact Industrial metal printing market.

On the other hand, integration of directed energy deposition technologies with subtractive CNC machining tools has grown significantly in the last couple years and helped to establish a stronger link between the additive and subtractive digital manufacturing processes. Furthermore, continued improvements within powder bed fusion technologies are being implemented in two ways, that are ultimately opposite of one another: improved productivity and increased accessibility, with the latter driving Compact Industrial Metal printing market growth.

The most notable contributors to the Compact Industrial metal printing market have been, and still are, Markforged and Desktop Metal. And, until recently, Aurora Labs and OR Laser were the only other notable Compact Industrial metal printer manufacturers that had shipped units, taking orders as early as 2016. Pollen AM and Additec are expected to ship units this year, and Xact Metal started shipping the 200C at the end of 2018 and expects to begin shipping the 200S mid-2019.

About SmarTech Analysis:

Since 2013 SmarTech Analysis has published reports on all the important revenue opportunities in the 3D printing/additive manufacturing sector and is considered the leading industry analyst firm providing coverage of this sector. Our company has a client roster that includes the largest 3D printer firms, materials firms and investors in the 3DP/AM sector.

For more details on our company go to www.smartechanalysis.com

Contact:

Robert Nolan

(804) 938-0030