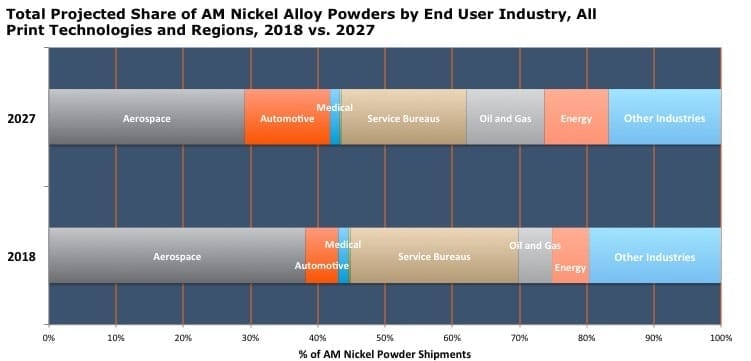

Charlottesville, Virginia: SmarTech Analysis, the leading provider of additive manufacturing market data and market analysis, has released a new market tracking and forecast database for nickel alloy additive manufacturing (AM) opportunities which shows nickel superalloys becoming one of the most advanced and high value metals amongst all printable metals in 2019. According to the report, the AM nickel powder group of alloys is expected reach $450M in worldwide sales to users of metal 3D printing technologies by 2027. This growth will be driven by a similar expansion in other popular nickel alloys which has been seen over the last year within the nickel superalloy subsegment. The latest report is part of a two-piece analysis package featuring a robust database on nickel-based additive manufacturing opportunities including powder shipments, hardware opportunities, pricing trends, market shares, and much more.

For more details on the report go to:

https://additivemanufacturingresearch.com/reports/additive-manufacturing-nickel-alloys-2019/

About the Report:

This two part resource is a continuation of a new series of market intelligence offerings from SmarTech Publishing which provides stakeholders in nickel-based additive manufacturing an off-the-shelf resource for market metrics and forecasts specific to a rapidly growing segment of the industry. The analysis is both broad and deep, with tracked data covering material shipments and revenues by end user industry and geographic region, as well as by consuming print technology and other metrics. The package can easily be plugged into existing internal market intelligence resources or dissected to provide business intelligence across organizations. The accompanying short report provides context for the data by analyzing the latest events and trends in the nickel alloy AM market as they relate to various forecasted data.

From the Report:

• Nickel alloys are some of the most widely used materials for applications with an extreme operating environment, making them commonly found in industries and applications in which metal additive manufacturing techniques are already being explored and applied. This is a net advantage for the development of the nickel-AM market, because the historical use of metal AM techniques like laser powder bed fusion have been, for the most part, relegated to high performance, high value components due to the cost structure of the technologies

• The early research and developments in nickel superalloys for aerospace engine components was also successfully ported to other industries where similar turbomachinery applications require performance similar to jet engines, especially in power generation for oil and gas and general energy markets, making materials like Hastelloy some of the most widely printed materials today. More recently, however, nickel materials have begun to gradually creep into other areas of application beyond the areas of turbomachinery and aerospace propulsion systems

• SmarTech anticipates that in the near term, nickel alloys will continue to see widespread expansion, especially through the development of printing parameters specific to new commonly used nickel alloys outside of the typical superalloys used today, for alloys such as the Monel family, Invar family, Incoloy family, and various Haynes nickel materials