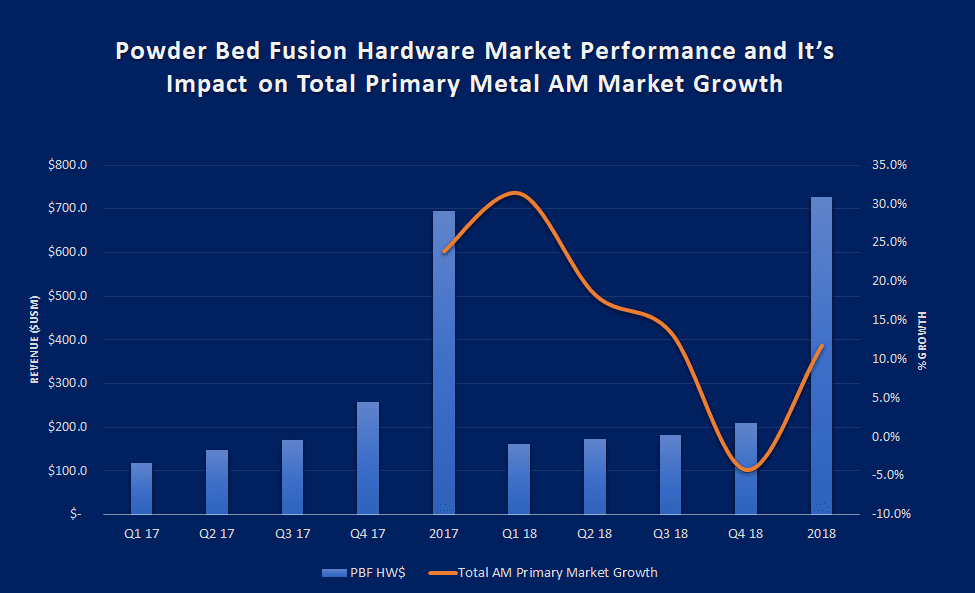

Crozet, VA: SmarTech Analysis, the leading provider of industry intelligence and analysis to the metal additive manufacturing industry, predicts that the recent challenging period for metal powder bed fusion technology market may be coming to an end. In its latest specialty metal additive manufacturing market report, SmarTech analyzes the current state of the metal powder bed fusion market, which has been marked by much slower growth over the past several quarters than the historical norm, prompting stakeholders to evaluate business strategies in the space. However, SmarTech believes that the short-term challenges appear to be waning and is projecting a return to more historical growth levels by the end of 2019 with some $880M revenue expected to be generated in metal powder bed fusion hardware sales throughout 2019.

For more details on the report, go to: https://additivemanufacturingresearch.com/reports/powder-bed-fusion-markets-a-metal-additive-manufacturing-market-analysis/

About the Report

The report, Metal Powder Bed Fusion Markets in 2019, is a study of the past, current, and short term outlook specifically for metal powder bed fusion technologies, which represent the largest portion of metal additive manufacturing today. The report provides a significant amount of detailed contextual metal AM market data showing the current and future positioning of metal powder bed technologies and the primary market opportunities associated with them, including machines and metal powder sales to support their use.

A competitive analysis of the key and upcoming players in the field is provided with quantitative insights on each company’s performance in the market based on product offerings in powder bed technologies, supporting business models and services, and technical innovations in the printers themselves. EOS, 3D Systems, Additive Industries, AddUp Solutions, GE Additive, Renishaw, SLM Solutions, Trumpf and Velo3D all addressed within the analysis.

Market data in the report includes a current breakdown of the metal PBF machine market by hardware classifications based on size and productivity of various systems offered today, as well as competitor market shares. Several data points are presented on a quarterly basis, providing short term insights and detailed trend visualization.

This study is an excellent resource for those stakeholders in powder bed fusion technology, including active machine or material suppliers, software developers, investment and financial groups wanting to understand the metal AM space in more detail, and startups developing technical solutions for powder bed technology.

From the Report

- SmarTech believes the lack of process-specific expertise and understanding of business-case development for specifically for metal additive (and powder bed fusion technology) to still be the key limiting factor in the market today as well as the catalysts for potential market slowdowns in the near term. Although a return to growth is predicted based on a number of cyclical factors (like hype cycles for other tech, increasing numbers of production oriented applications from existing users beginning in 2020, etc), SmarTech believes it would be unwise to fail to recognize the potential for continued market turbulence.

- The interconnected nature of the technologies in the industry that are driving adoption mean that advancements in process simulation or design for additive software could hasten metal AM becoming more accessible to a wider audience. New solutions that help identify specific parts as effective candidates for additive manufacturing, such as those from startup 3YOURMIND, also could potentially play a role in advancing growth prospects more quickly by lowering the barrier of expertise currently needed.

- Currently, Titanium, cobalt, aluminum, nickel, and precious metals are expected to be processed by powder bed fusion technology at levels above the total average share of all powder bed fusion material consumption over the forecast period. This means that, powder bed fusion technology adoption will be driven by demand for printing these materials in a market where no other technology is expected to provide the same level of production flexibility and reliable material processing in these metals.