In the latest report, 3D Printing Software Markets – 2016: A Ten-Year Forecast and Opportunity Analysis SmarTech Publishinganalyzes 3D software market trends and growth forecasts to 2026 and describes eight different tool types within four different major workflow patterns.

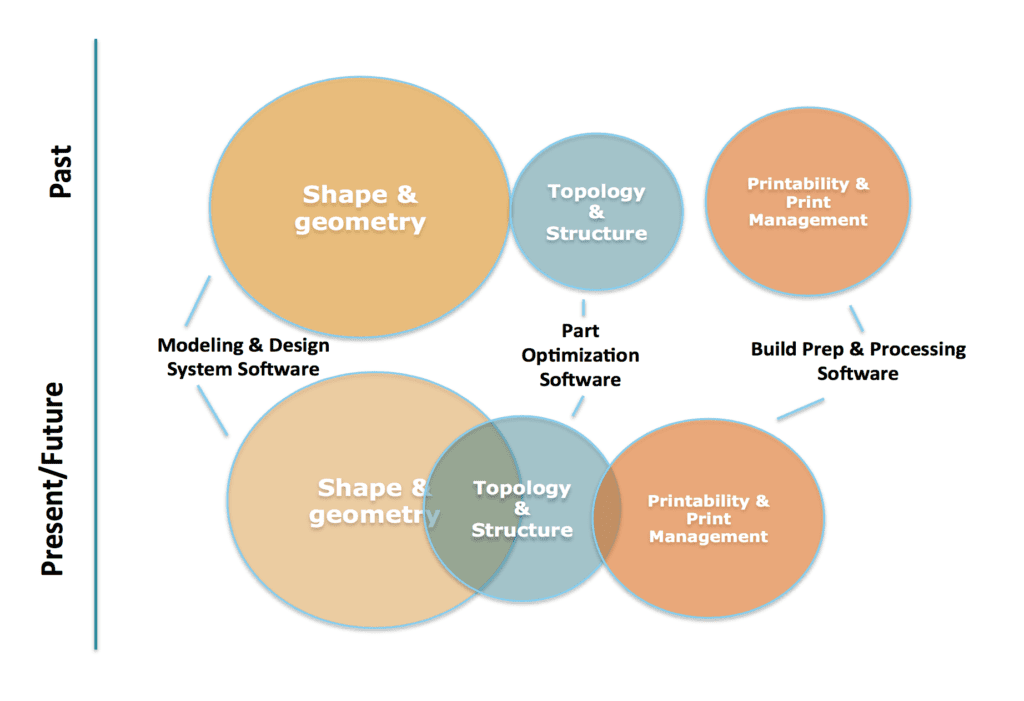

Image below visualizes the convergence of design and workflow software with regards to 3D printing.

Credits: SmarTech Publishing

Over the last year to eighteen months, the market for 3D printing software has seen a significant uptick in commercial activity, investment and development initiatives. This activity is mostly dominated by large global entities involved in software development and SmarTech Publishing is seeing some important software trends three of which we summarize below:

#1 Printer OEMs Developing Tightly Integrated, Machine-Specific Print Preparation Tools

During 2016 3D Stratasys announced a significant new software product called GrabCAD Print, designed to provide a single integrated tool and interface to manage the post-CAD printing process. GrabCAD allows the import of CAD files directly from various popular CAD programs such as Solidworks or AutoCAD. Thus, the software appears to encompass elements of build preparation, build processing, and production management within the context of some Stratasys FDM printers.

Meanwhile vendors of metal additive manufacturing systems have also begun to develop and market more advanced hybrid build preparation-processing software tools specific to the challenges and needs of users of metal AM. Renishaw, whom has significant business activity in software development for technologies other than 3D printing, has now developed its QuantAM build preparation software for use specifically with its own metal powder bed fusion systems.

QuantAM is a fairly pure-play build prep software optimized for tight integration (and therefore efficiency) with its own hardware and offers an alternative to metal AM systems which rely on third party software such as netfabb or Magics. And 3D Systems announced in September 2016 its newest metal AM software offering designed for use with its Direct Metal Printing line of metal powder bed fusion systems.

#2 CAD Leaders Seeking to Build Out ‘Direct to 3D Print’ Features as a Competitive Advantage

The major players in traditional 3D CAD software have also been rushing to build out features allowing a ‘direct printing’ option, seeking to emulate the simplicity of word processor-like printing which is direct from design to printer without in-between tools to prepare files or optimize them for printing. Additive manufacturing/3D printing has been clearly identified as a next generation growth market for CAD tools and 3D design software for the last five years in particular, and today major players such as Autodesk and Dassault Systemes are dedicating more feature releases aimed directly at users of 3D printing.

In February 2016, Dassault Systemes highlighted planned integrations for its flagship SolidWorks CAD software with regards to 3D printing. The company is seeking similar goals as major hardware OEMs in that they hope to eventually reduce or eliminate the convoluted software chain often involved in going from digital design to physical part.

For now, the company is focusing on working to integrate direct printing from CAD for low cost and desktop printers, having partnered specifically with South Korean 3D printer manufacturer Sindoh (at least initially). New features for users of Sindoh printers using SolidWorks will emulate the print preparation and build processing stages within SolidWorks itself.

Meanwhile, Autodesk continues a similar strategy with the latest in AutoCAD 2017. The latest generation of the venerable AutoCAD includes Print Studio –a companion piece which had previously been developed on the AutoDesk Spark platform for use with its own desktop 3D printer. Now part of AutoCAD itself, Print Studio integrates its own build preparation and processing functionalities, borrowing some features from other Autodesk products (such as MeshMixer) to enable printing directly from CAD software.

This functionality is clearly designed around the concept of desktop material extrusion or photopolymerization printing, but is not necessarily limited to any particular segment of the market. This flexibility in turn limits the functionality of the preparation software compared to industrial level prep tools or machine-specific preparation tools.

In addition to the major players adding lower-functioning ‘direct to 3D print’ features, new players in the CAD market such as Onshape are building out new CAD tools from the ground up with flexibility to integrate 3D printing specific features through the cloud based architecture.

Onshape is fully functional professional CAD tool operated from a web browser which began a public beta test in 2016. Of note regarding 3D printing integration, the utilization of a cloud based platform and more open software development architecture allows third parties to develop apps for the Onshape platform, and 3D printing software giant Materialise has now released an app for Onshape users to allow for print preparation of designs.

#3 Third-Party Developers Emerging in Metal AM Software, Materialise Continuing to Evolve Existing Market Leading Products

The market for third-party 3D printing software is expected to grow even faster than that of machine-specific software developed by printer OEMs, thanks primarily to the need for software that can deal with a wide array of potential applications and print processes to support them.

Materialise has announced/released updates over the last six months to two of its flagship products—Mimics Innovation Suite and Magics. The application-specific Mimics Innovation Suite for medical 3D printing applications is now in its 19th iteration, with its latest round of feature additions focused on improving the overall efficiency of various time-consuming processes associated with importing medical imaging data, converting it to a three-dimensional file, and making necessary revisions for a printable medical device or implant.

Meanwhile, the market leading print preparation and brand agnostic build processor suite Magics is receiving similar updates in its latest revision. Of note in the latest Magics offering is the new Materialise Magics Print module, which is intended for printer OEMs to be able to package with their own printers to offer customers a very flexible and effective third party print preparation and processing tool which can be accommodating to multiple printers and technology types.

New third-party software developers are also beginning to enter the realm of commercial relevance, especially in the area of metal additive manufacturing. German start-up Additive Works is currently beta testing its flagship product Amphyon, designed to be a brand-agnostic metal AM print preparation and processing software which includes elements of simulation-driven analysis for the popular laser based metal powder bed fusion process, which can help engineers eliminate built-in stress and print failures when printing metal parts.

Not all third-party developers are seeking to revolutionize the software market with more integrated tools aimed at reducing the current process chain—developers such as Avante Technology in the U.S. are releasing new professional print preparation tools for complex .STL file fixing, but at more competitive and accessible price points. Avante’s latest Emendo Automated STL Repair and Validation tool allows for advanced and professional level file repair for just $80 per single user license.

About the Report:

In this report, the first ever of its kind, SmarTech Publishing explores the opportunities in development of 3D printing software tools ranging the entire 3D printing process from design to workflow and beyond. By defining the critical software functionalities of 3D printing in various contexts, this study segments the 3D printing software and 3D scanning software markets in a way that industry stakeholders can use to attack the next generation of software development opportunities.

The report also features for the first time an entirely purpose-built 3D printing software market forecasting methodology, allowing for an unprecedented level of market forecast data specific to 3D printing and scanning software opportunities. Included in the report’s forecasts are:

- Ten year forecasts of revenue opportunities for 3D printing and scanning software by tool category, as defined by the study, from 2015 to 2026

- Revenue opportunity data cuts by key adopting industries from automotive, to medical, aerospace, and many more

- Estimates and forecasted site-based opportunities for 3D printing software sales sold on site-based license structure by industry

- Pricing trends, printer installation data, and much more

Click here for more information on this report https://additivemanufacturingresearch.com/reports/3d-printing-software-markets-2016-a-ten-year-forecast-and-opportunity-analysis/

About SmarTech Publishing:

Since 2013 SmarTech Publishing has published reports on all the important revenue opportunities in the 3D printing/additive manufacturing sector and is considered the leading industry analyst firm providing coverage of this sector.

Our company has a client roster that includes the largest 3D printer firms, materials firms and investors. We have also published reports on most of the important revenue opportunities in the 3D printing sector including personal printers, low-volume manufacturing, 3D printing materials, medical/dental applications, aerospace, automotive, and other promising 3D market segments.

To Purchase this Report:

If interested in receiving a quote or to purchase this report, please email missy@smartechpublishing.com

Press Contact:

Lawrence Gasman

lawrence@smartechpublishing.com

434-872-0450