February 21, 2019

Crozet, VA: SmarTech Analysis, the leading industry analysis firm specializing in additive manufacturing (AM) markets, has published a new report on AM adoption in the eyewear industry titled, “Markets for 3D-Printed Eyewear 2019-2028” which forecasts of revenues generated by additive manufacturing in the eyewear industry through 2028.

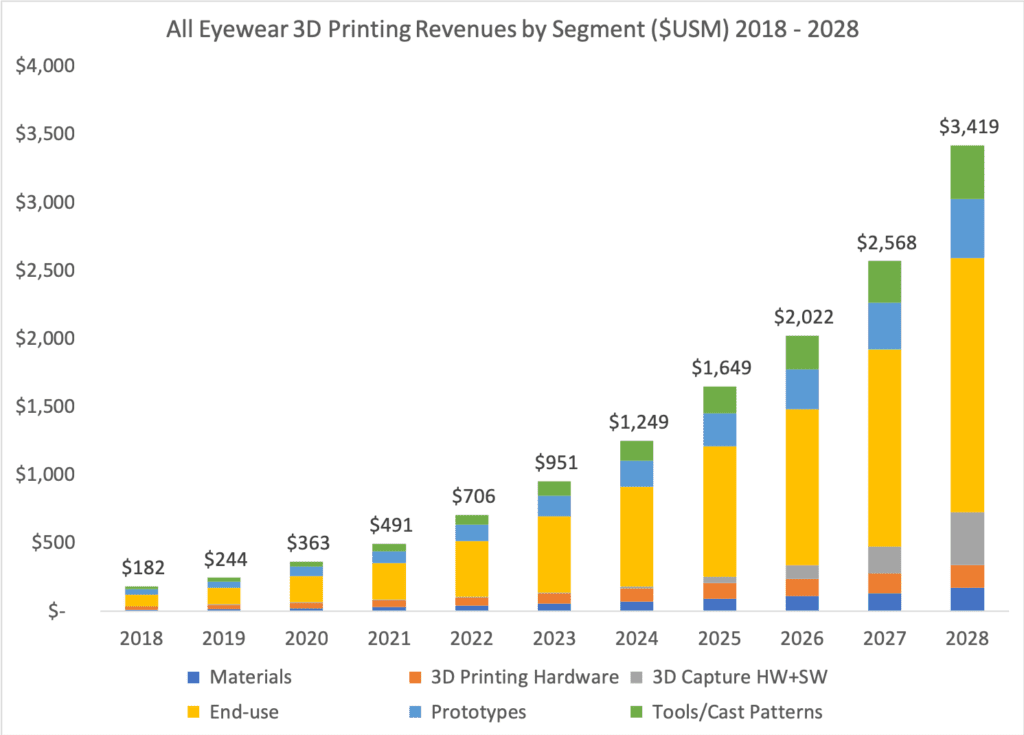

SmarTech projects the overall business opportunity for AM in the eyewear industry, which is expected to total $3.4 billion in 2028. This figure includes both AM industry segments (hardware, materials, services, software) and AM applications (prototyping, tooling/casting, final parts).

For more information on the report including a downloadable excerpt go to: https://additivemanufacturingresearch.com/reports/3d-printing-eyewear-market-2019-2027/

About the Report:

This report analyzes the key trends and stakeholders that are driving the eyewear mass customization revolution as well as the elements that are limiting AM adoption.

Leveraging its knowledge of 3D printing processes and unique database of global AM materials and hardware sales, SmarTech explores the key applications for AM in the eyewear industry, including both current and upcoming relevant case studies, as well as probable future developments. One primary objective of this report is to highlight the most relevant business opportunities that lie ahead for companies that are invested in the AM industry, including materials, hardware and service providers.

The other primary goal is to provide eyewear industry stakeholders with an accurate description of all currently existing AM technologies, materials and services (including 3D capturing and online customization software) that could offer a powerful competitive advantage as eyewear users demand increasing customization options. While final part production is a major focus area for the medium and long term, the report also analyses other current uses of AM in the eyewear industry, such as advanced and desktop prototyping, tooling and investment casting.

Key AM companies included in this report are Carbon, DWS, EOS, Formlabs, Fuel 3D, Glasses USA; Hoet, Hoya, HP, Luxexcel, Luxottica, Materialise, MONOQOOL, Mykita, Protos, Safilo, Sculpteo, Seiko, Sfered, Sisma, Specsy and several others.

From the Report:

• The single most significant segment in eyewear AM is final parts production, which is expected to grow into a $1.9 billion opportunity in a segment that will be worth $3.4 billion overall by 2028.

• The key technologies used in eyewear 3D printing are material jetting for highest level prototyping and powder bed fusion for final part production. Vat photopolymerization is also used today mostly for lost wax casting processes (and some part production) while filament extrusion is used for basic desktop prototyping and some end-use internal parts.

• According to available data, the overall existing industry for ophthalmic eyewear generates revenues of more than $100 billion a year This industry is growing in several ways with mass customization an important trend. Users increasingly expect to be able to purchase eyewear products that are tailor made for them.

• The 3D printed eyewear segment is expected to be a relatively small part of all 3D printed consumer products, both in terms of materials and hardware demand, due to the relatively small size of the parts being printed. At the same time, it is also one of the very first segments (together with footwear and some design products) that has already made significant strides toward end-use part production with additive technologies.

• The primary material used in all polymer powder bed fusion technologies for eyewear manufacturing is nylon 12 (PA122) which is the most widely used materials for this type of processes for any application. Some 3D printed eyewear manufacturers have developed special finishing processes to deliver a smoother surface finish and more vibrant color, while reducing the materials porosity.