As I put together my upcoming report on compact industrial metal printers, I can’t help but wonder why some of the competitive low-cost options on the market have been completely overshadowed by Desktop Metal and, to some degree, Markforged. Companies such as Aurora Labs, OR Laser and Pollen AM have had “desktop-like” metal solutions on the market for years but all three combined have only a fraction of the name recognition. I’m not saying that Desktop Metal and Markforged don’t offer great printers. But some might think they are the only two solutions available for those looking for a compact, industrial, low-cost metal 3D printer. Why is this? Is it just marketing? Or the existence of large corporate backers? Or the ability to get Fortune 100 names on their boards? I suppose it’s all three.

But, where does that leave us, the consumer? How do we sort the hype from reality? What are the evaluation criteria we need to be considering?

At the end of the day, it all comes down to how and why it’s going to be used. Coming out of AMUG last week my opinions were confirmed by much of the content presented and conversations had: 2019 is the year of application-specific development and corporate partnerships. The former is more pertinent here. What I mean by that is that after the hype 3D printing experienced in the early part of this decade, we dropped into what the Gartner Hype Cycle labels the “Trough of Disillusionment”. We are now entering the “Slope of Enlightenment” portion of the curve, and one major driver for this positive course correction is the broad consensus that 3D printer manufacturers are not necessary competitors, but actually allies, all critical to complete the puzzle. There are the ever-critical edges and corner pieces that helped us begin to form the picture, and then a larger number of middle pieces that are more difficult to find and place, but no less critical. Those middle pieces can not and should not be ignored.

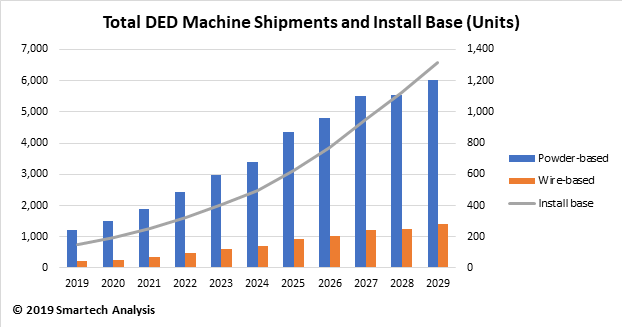

So, coming back to distinguishing hype from reality, we need to first ask ourselves what it is that we actually need. This lack of clarity and definition generally drives those wanting to invest in 3D printing to lean towards the solutions with the most ubiquity. In some cases, this is the right decision; not one based on knowledge and facts, but rather luck. There are amazing powder bed fusion (PBF) solutions, innovative material extrusion (ME) solutions, and reinvented Directed Energy Deposition (DED) solutions. So, how do you choose? It’s a matter of defining your needs. PBF printers have great resolution and surface finish, but with more complex material handling and a steep learning curve. ME solutions offer relatively easy user interfaces, but complicated and lengthy sintering steps. And, DED has speed and cost on its side, but an entirely different level of resolution. At the end of the day, no one can say one technology is better than another, as its more a function of the intended use.

Many companies with impressive compact industrial metal printers are taking 2019 to either enter the market or expand on their existing presence. It’ll be very interesting to see which one’s can approach the Goliaths (or Unicorns, in this case) with enough power and substance to make a mark.

Blog by Kristin Mulherin, Senior Analyst at SmarTech Analysis

Contact: kristin@smartechpublishing.com