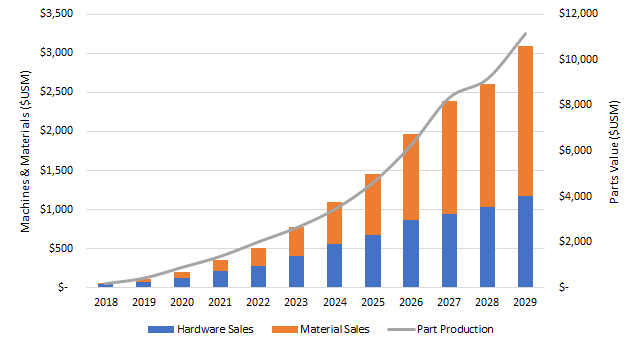

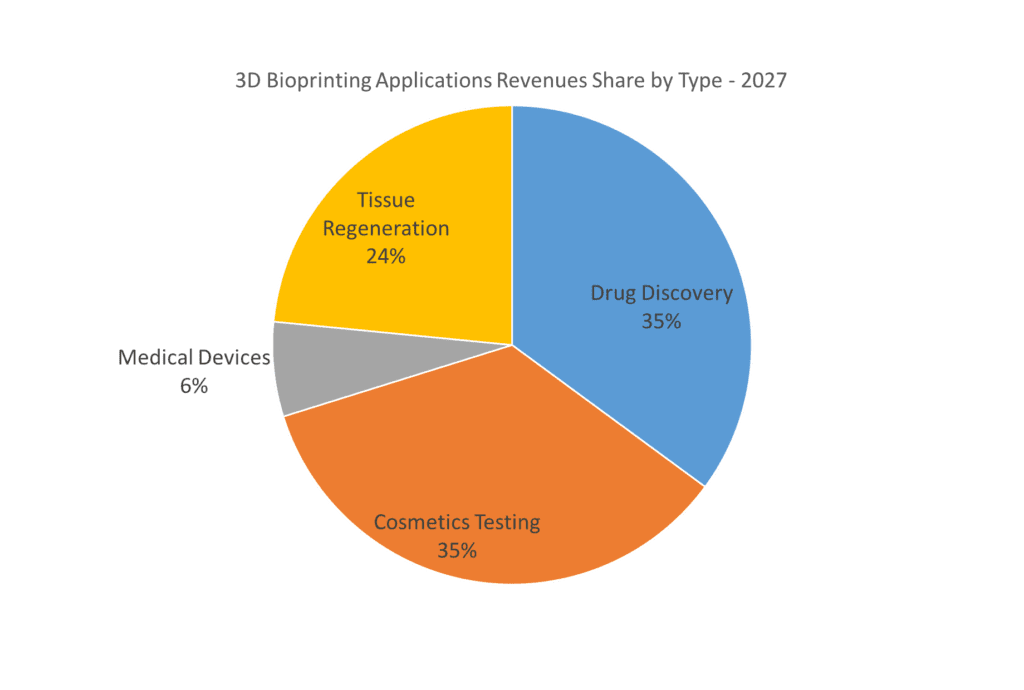

SmarTech Publishing, a leader in vertical markets research focused on adoption of 3D printing technologies has published a new report titled, Bioprinting Markets: Materials, Equipment and Applications – 2017 to 2027: An Opportunity Analysis and Ten-Year Forecast, the first ever in depth analysis of business segments and financial forecast for the rapidly evolving field of 3D bioprinting. In analyzing the different market drivers for bioprinting hardware and materials, the report highlights how current applications for in-vitro bioprinted tissues in drug discovery and cosmetics testing are expected to become a major business opportunity with over half a billion dollars in yearly revenues by 2027.

The chart shows the forecasted market share for each of the primary bioprinting applications in 2027. Cosmetics testing and drug discovery are expected to be the two main applications in terms of revenues, although tissue regeneration might become an even larger opportunity beyond the forecast period.

Credits: SmarTech Publishing

Ethical, real, bioprinted in-vitro animal and human tissue

Drug and cosmetic toxicity testing are two very large global markets where 3D bioprinting technologies have already begun to show significant benefits:

# 1. More accurate drug testing can save lives. Fully human 3D bioprinted tissues, with spatially-controlled architectures, enable biochemical, genetic, and histologic analysis following exposure to specific agents, making them valuable in-vitro tools for toxicology and disease modeling. Organovo’s ExVive liver tissues have already proven useful in preclinical toxicology assessment, especially in situations where chronic exposure, bioactivation, interactions among several cell types or tissue level phenotypes are critical components of the toxic response. 3D bioprinting has also been shown to enable the investigation of cancer progress, including tumor heterogeneity, leaky tumor vasculatures, cancer metastasis, and patient specific anticancer drug testing.

# 2. More accurate drug testing is worth billions. According to Organovo, the market for liver and kidney in-vivo tissue testing is currently valued at close to $3 billion combined. As bioprinting proves to be a cost-effective and efficient solution, its value in this field is expected to grow from the current $11 million to several hundred millions of dollars over the next decade.

# 3. Animal testing for cosmetics will disappear. Bioprinting applications, including 3D bioprinted tissue and even hair follicles, are very attractive to cosmetics companies, especially in Europe, where animal testing for cosmetics was banned in 2013. L’Oreal USA and Organovo teamed up in 2015 to automate the production of living, breathing skin samples using 3D bioprinting. L’Oreal produces roughly 100,000 skin samples every year, yet the current process of growing donated tissues is very costly (reportedly up to €62/piece). For the beauty company, the advantage will be the ability to economically and ethically test products (i.e. not on animals) across varying skin types for more accurate results.

# 4. Partnerships between global corporations and bioprinting pioneers are already in place. Cosmetic giant L’Oreal also signed a research agreement with French biotech company Poietis in 2016 to bioprint follicles capable of actually growing hair. Not only could this lead to more effective testing of hair products, it could also advance understanding of how hair functions, leading to viable, biologic solutions for adult hair loss. Poeitis has also teamed up with BASF to create 3D printed skin for cosmetic and drug testing. Procter & Gamble has similarly joined the race to develop 3D printed skin samples, investing some $44 million in 2015.

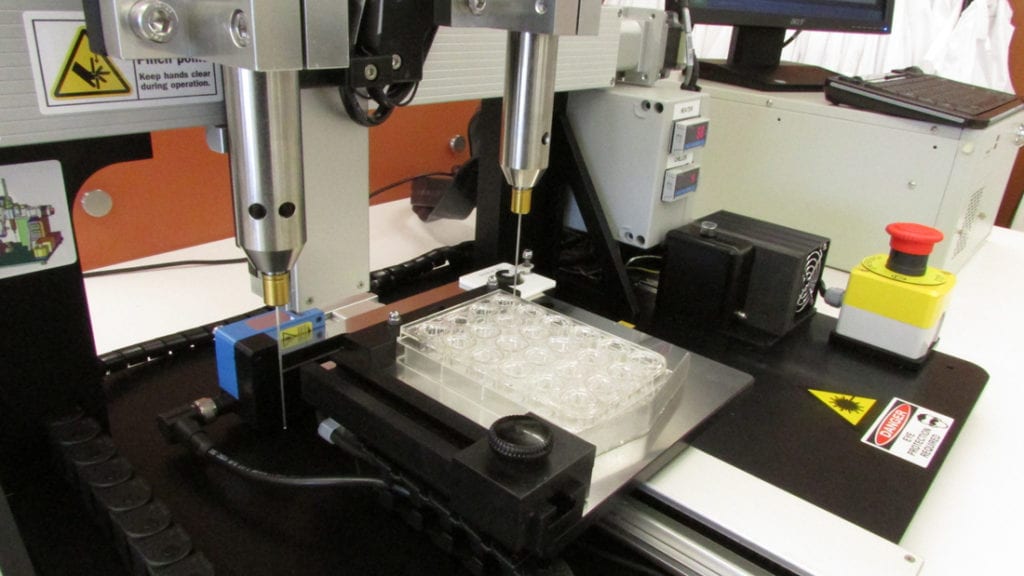

Organovo was one the first pioneering company to develop 3D bioprinted liver and kidney tissue for drug discovery applications through its own, internally developed 3D bioprinting technology.

Credits: Organovo

While the single biggest long term opportunity for 3D bioprinting technologies could be in tissue and even organ regeneration, the applications that have already begun to generate revenues today are found in drug discovery and cosmetics testing. While still largely experimental these have already provided an indication of the benefits that they could offer within the forecast period considered for this report, promising exponential growth rates that are likely to drive the hardware and materials market along. Today there are only a handful of companies that are ready to exploit these opportunities however the market for commercial 3D bioprinting is ready to bloom and move beyond the academic research. If and when that happens this could result in one of the biggest opportunities for all of 3D printing.

About SmarTech Publishing’s Bioprinting Markets Report

SmarTech believes that the potential for the bioprinting sector has increased considerably in the past couple of years. What we are seeing is that (1) bioprinters themselves have technologically matured and (2) they have also become more accessible in terms of cost to a wider target of users — low-cost desktop bioprinters are available at below $20,000. Meanwhile, bioprinting is experiencing a rapid transformation from basic research in academic laboratories to an emerging industry due to its near-term potential in areas such as drug discovery, personalized medicine, regenerative medicine, cosmetics testing, medical devices and food manufacturing. While printing complete organs still seems a long way off, revenues from bioprinting are already being generated from these more immediate applications. SmarTech’s analysis suggests that by 2027, bioprinting applications will generate over $1 billion in revenue, accompanied by a healthy market in specialist bioprinting hardware and materials.