According to SmarTech Publishing’s latest report on additive manufacturing with titanium – Titanium Opportunities in Additive Manufacturing — 3D-printed titanium will have a critical strategic role in producing low-weight, highly efficient cars.

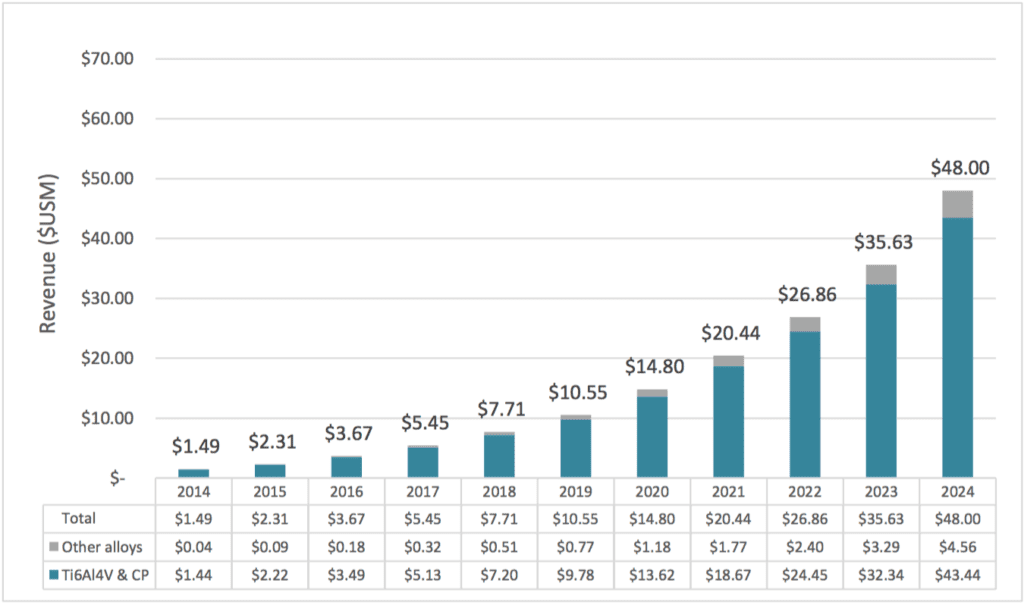

Within the automotive industry, the motorsports sector will be the primary users of 3D-printed titanium parts. At present the value of the titanium consumed is tiny. However, by 2019, the value of titanium consumed by the automotive sector will exceed $10 million and by 2024 it will be close to $50 million. Throughout the period we expect to see titanium demand within the automotive sector come mostly from continued use for high-performance parts in racing vehicles. By 2024, the automotive is expected to utilize 103 metric tons in annual demand of titanium and titanium alloys powders.

SmarTech Publishing forecasts that global revenues for titanium use in the automotive sector will grow faster after 2019 to reach $48 million by 2024

Progress Towards 3D-printed Titanium in Automotive

Several factors suggest to us that 3D-printed titanium has a future in the automotive industry:

# 1. 3D-printed titanium is already being used. As the picture of activity at Monash Motorsport shows below, there is already some serious activity in this space. So there are already small beachheads for printed titanium in car manufacturing of a certain sort

#2 Perfect for lightweighting. For non-cost sensitive automotive industry projects with a lightweighting goals, 3D-printed titanium is the ideal material; both 3d-printing and titanium contribute to making parts lighter. Combining them would be a winning combination. This may prove even truer as electric cars become more commonplace, with lighter car bodies and parts playing an even greater role in increasing fuel economy.

#3 Improved titanium-based designs. Automotive manufacturers have struggled with integration of titanium into designs, but 3D printing is helping to break down barriers thanks to increased production effectiveness. In our opinion, 3D printing could prove to be a catalyst to for further use of titanium in automotive, with eventual benefits in terms of increased product performance for the car industry as a whole.

Monash Motorsports (MMS) teamed up with the CSIRO’s Lab 22 that specializes in the additive manufacturing of titanium 6Al-4V, to 3D print hubs and interchangeable uprights. (Credits: www.monashmotorsport.com)

The impact of these market drivers is expected to accelerate as the cost of titanium additive manufacturing goes down. Efforts to reduce these costs are already underway. These consist of (1) reduction of AM system cost itself, as well as (2) alternate titanium powder production methods to reduce actual material cost per kilogram of titanium. Both avenues would ultimately reduce cost of 3D printed titanium parts for automobile manufactures and potentially result in increased titanium powder demand in the automobile industry

It is still not immediately clear if 3D printed titanium will make significant inroads beyond the motorsports segment and into commercial vehicle markets. Other metals could prove more efficient and cost effective for automotive parts production. On the other hand due to its excellent weight-to-strength ratio, titanium may prove particularly effective in driving 3D printing adoption in the automotive industry as a whole.

About SmarTech Publishing’s 3D-Printed Titanium Report

Titanium Opportunities in Additive Manufacturing — presents both ten-year market forecast data as well as critical market analysis for 3D-printed titanium use in key end-user industries such as automotive, aerospace, medical and dentistry. It also discusses the primary opportunity factors related to the broader supply chain, primary providers of AM titanium powder and other forms, and an analysis of the print technologies and powder production processes associated with 3D-printed titanium.

If interested in receiving a quote or purchasing this report, please contact missy@smartechpublishing.com.

About SmarTech Publishing

SmarTech Publishing is the leading provider of market research and industry analysis in the 3D printing/additive manufacturing sector. We have published reports on most of the important revenue opportunities in the 3D printing sector including personal printers, low-volume manufacturing, 3D printing materials, medical/dental markets, aerospace, automotive and other promising 3D market segments. Our client roster includes some of the largest 3D printer firms, materials firms and investors in the world.

Contact:

Lawrence Gasman

lawrence@smartechpublishing.com

434-872-0450